ZEPHYRUS HVLS FANS

Features and Benefits

Kale Zephyrus series is a new generation of industrial energy-saving fan products of Kale. It has a new PMSM permanent magnet motor platform, and its maximum diameter can reach 7.3 meters. Generating three-dimensional natural wind lets you quickly cool down in the hot summer sweat and have a natural comfortable experience. The shape design of Kale Zephyrus is a design scheme jointly developed by Kale and a well-known industrial design team in the industry. The design inspiration comes from the natural phenomenon "volcanic lava". And the products are extremely industrial beauty. Even a casual glance will leave you with a deep impression!

Primary Components

PMSM Motor

New motor with optimized balance design

Ideal design, high protection grade maintenance free

Efficient Operation

Extremely Silent

Motor Maintenance-free

Control System

Schneider electrical sets, with built-in safety protection module which will interrupt the output automatically in case of some accidents. International(Danfoss & Scheider)brand control cabinet, passed EMC by SGS and CCC certificates, meanwhile, passed anti-creeping tests which shield electromagnetic interference effectively. The protection level is IP55, passing UL, EMC, LVD, and ROHS certificates.

Aviation Airfoil Fan Blade

The aviation airfoil fan blade adopts the industry-leading brand-new fan blade fixing structure, built-in safety parts design, and multi-dimensional safety guarantee.

Two sets of fan blades are designed with through ribs to make the blades more rigid and ensure the fan's air supply efficiency.

Winglet

The dovetail power fan blade design is inspired by the aviation airfoil, with excellent aerodynamic performance, which can minimize wind resistance and convert electrical energy into kinetic energy of air with the highest efficiency.

Connector for Fan Blade

KALE's unique patented jacket-type connector adopts three cold forging processes + magnetic force grinding process + anodic oxidation process, aviation hard aluminum 7050 aging heat treatment, certificated by the national quality inspection center, it bears more than millions of times of fatigue experiment, completely solve the break and drop problem caused by long time running!

Installation Condition

We highlight the essential role of the installation process by stressing strict compliance with standards and the need for professional expertise to resolve any uncertainties.

1.Tailor the installation plan to meet site-specific requirements.

2.Utilize equipped lift trucks for streamlined installation.

3.Leverage expert experience in debugging levels, heights, and balance.

4.Conduct dynamic balancing tests to ensure stable fan operation.

5.Employ torque-standard fasteners for optimal fastening.

6.Implement a safe, efficient, and professional installation process.

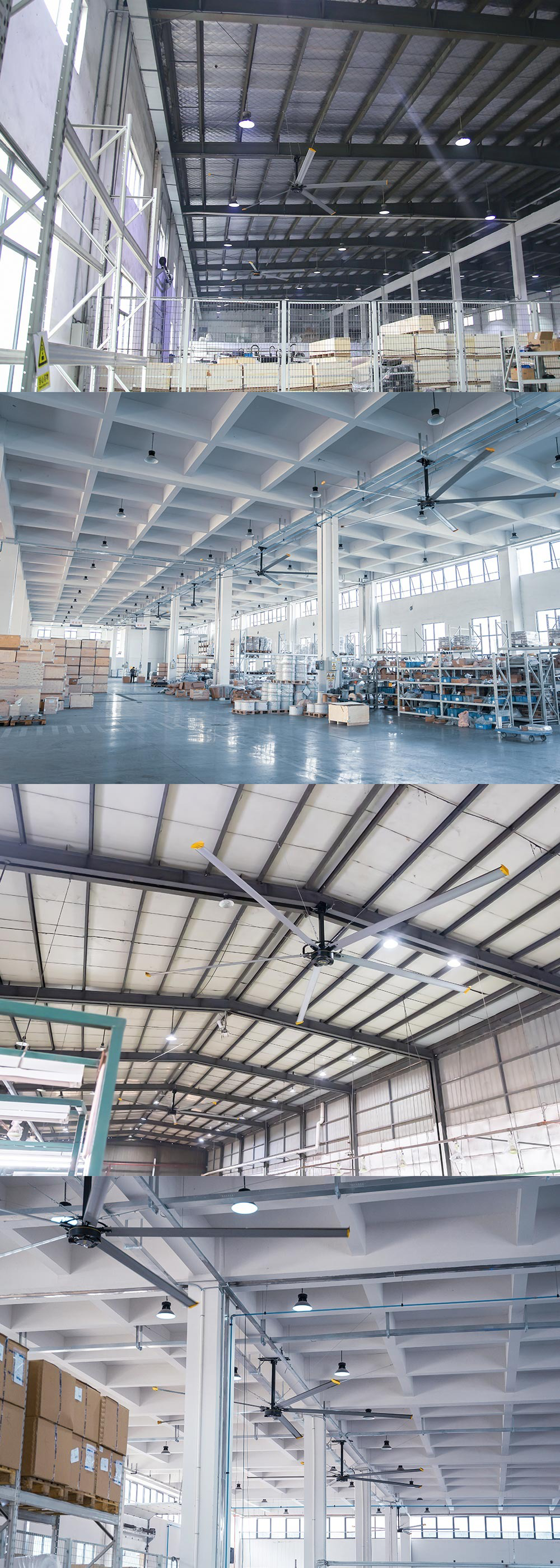

Application

Zephyrus HVLS ceiling fans, available in various sizes, are highly versatile for diverse industrial applications, including:

Factories and Warehouses: Enhances air circulation and optimizes working conditions.

Manufacturing Plants: Regulates temperature for precise processes.

Food Processing Facilities: Controls humidity to ensure product quality.

Agricultural Storage: Maintains optimal conditions for crop preservation.

Animal Farming: Enhances ventilation for a healthy livestock environment.

Automotive Workshops: Improves air circulation and removes fumes for a safer workspace.

Chemical Plants: Manages fume dispersion to ensure worker safety.

Textile Mills: Regulates temperature and humidity during production.

Pharmaceutical Production: Supports sterile conditions in cleanroom environments.

Construction Sites: Mitigates heat and dust for worker comfort.

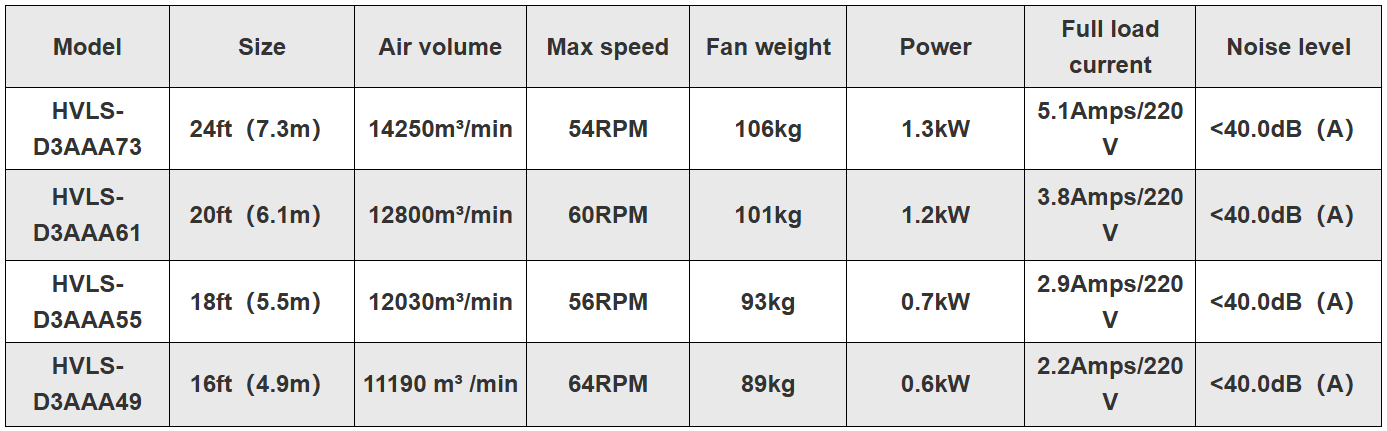

Technical Specifications